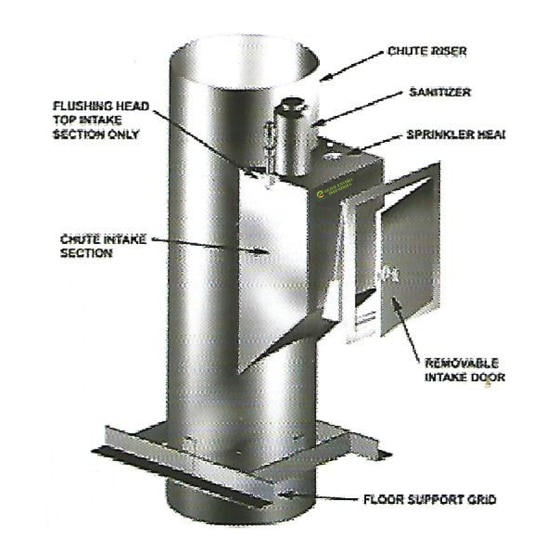

Intake Door

- Intake Door are self-closing, with a favourable latching system.

- The front is fabricated of polished stainless steel with matt steel backs.

- Steel angle frame with 3-1/2” steel extensions.

- Integral polished stainless steel trim, with the top side embossed, designating the use of a chute.

- Pivot-type hinge welded to the door frame.

- Door equipped with chrome-plated kye locking “C” handle latching assembly.

Material of Construction

-

1

Stainless steel S.S. 430/S.S. 304

-

2

G.I. – Galvanized Iron

-

3

M.S. OR CRC

The thickness of chutes is 1mm /1.2mm /1.6mm per diameter.

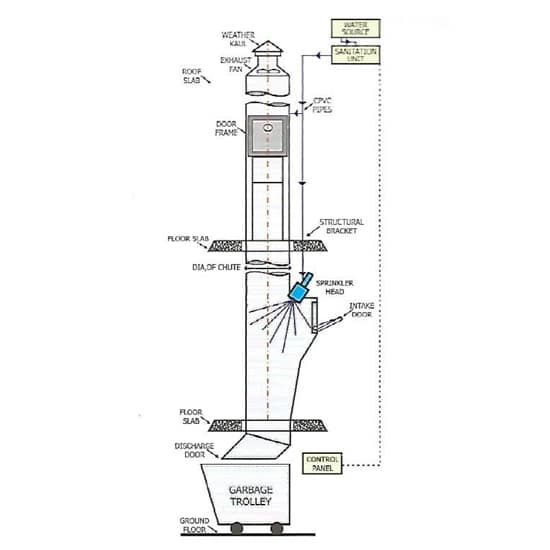

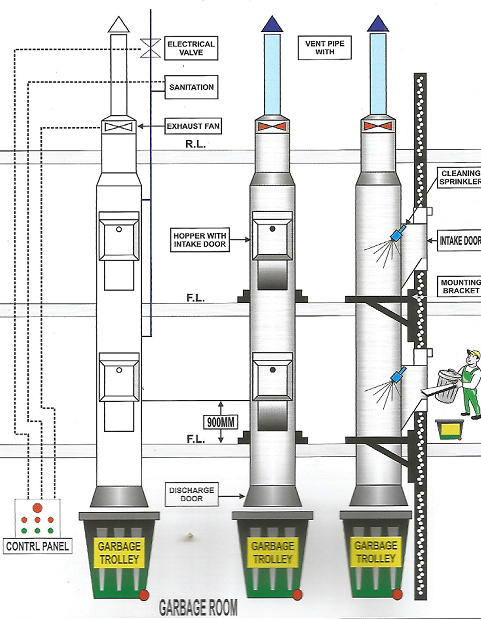

Venting

- This for removing foul smells and gases generated in the garbage chute.

- Vents are made of the same diameter or reducing the diameter of the chute and extend 4ft above the roof of the building.

- Exhaust system in the top of remove decomposed smell and gases with a fan of average speed.

- 300 CFM-900 CFM depends on the number of floors.

- Ventilation is operated automatically (Timebase) by electrically operated control penal.

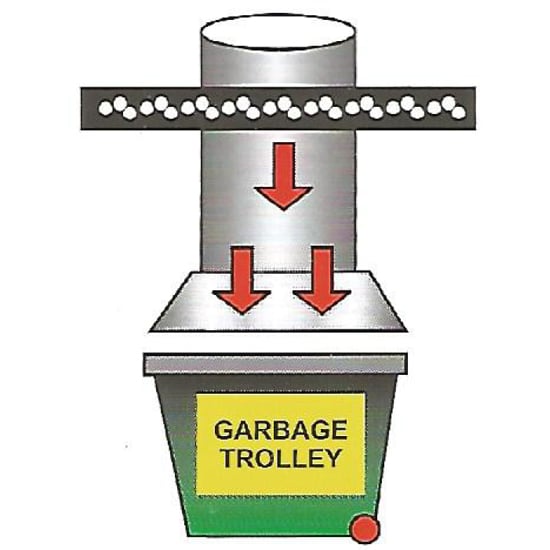

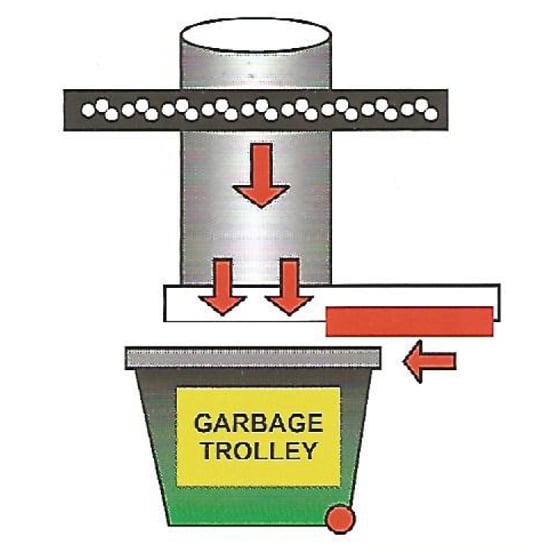

Discharge

- Chute shall directly discharge into trolley or compactor.

- Diversion shall not be allowed. Max Diversion of 15 with vertical allowed as per codes.

When a door is not required, We provide a conical hopper to avoid spoiling garbage, and it is directly connected collection trolley.

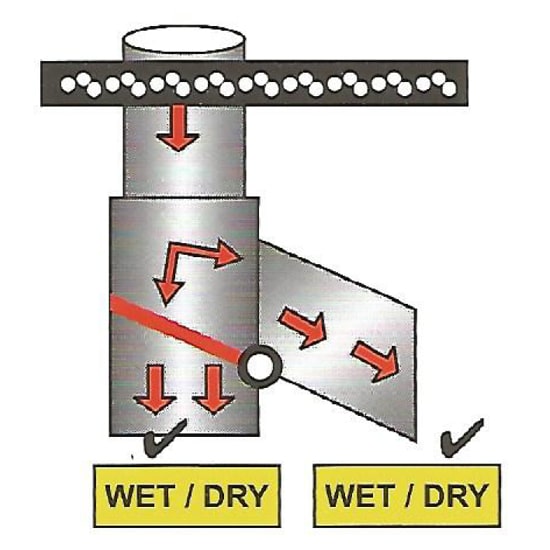

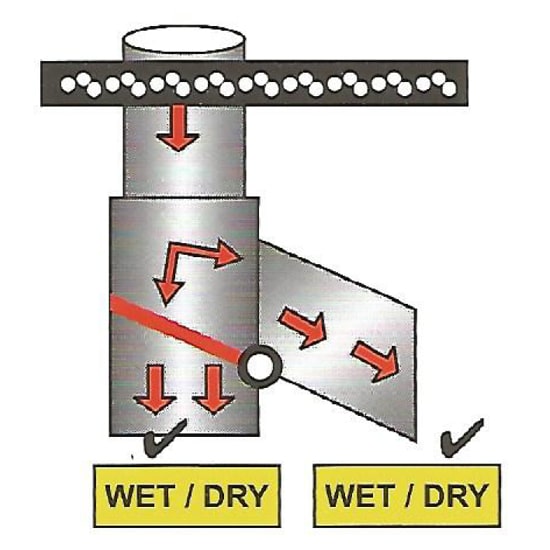

- It is specially designed for the separation of wet and dry garbage.

- A mechanically operated rotating flap is provided to divert dry garbage.

- The electrical control panel operates this System.

The standard sliding discharge door is mounted on a bearing in a sloping position and held open with a 79-degree U.L. approved fusible link. In the point of fire in the garbage room, the fusible link melts, and the door shuts the mouth of the chute, restricting heat transfer. Mainly used in Garbage Chutes. Control panel.

- Top hinge type discharge door is held horizontally against gravity by 79 C. fusible link in case of fire, fusible link melts, and fire door closes the upward path of chute restricting heat transfer mainly used in Linen chutes.

Chute Cleaning

- Cleaning the chute from the inside is a very important procedure to maintain hygiene.

For cleaning chute, we provide TWO Options

This Cleaning has been done by normal water coming from the overhead water tank, and it is operated and controlled by an electrically operated valve. This valve is fitted at the top of the chute and outlet of the water tank. This System operated on manual mode as well as automatic mode, also.

Disinfecting and Sanitizing Unit

This Cleaning has been done with normal water with disinfectants, and it is added in line by a Motorized pump. This System is operated and controlled by an electrical control panel. This Unit is installed at roof level. This System operated on manual mode as well as automatic mode also.

General Requirements for Chute Installation at site

Required Minimum Duct Size for Installation

| CHUTE DIAMETRE | DUCT SIZE / SLAB OPENING |

| 450mm | 600mm * 600mm |

| 600mm | 750mm * 750mm |

| 750mm | 900mm * 900mm |

- The front well shall be constructed after the erection of the chute.

- Provide appropriate single phase power point with earthling for the control panel in Garbage Room.

- Provide predefined water connection with an isolation valve.

- Provide 1” wet riser from fire protection system for total building height inside.

- Chute duct (OPTIONAL)

Material of Construction

- The room shall be a tight air non, ventilated room

- No windows or louvres shall be provided in the room

- Provide wall tiles (min. 1.8mtr. high) & Floor tiles.

- Floor to have a proper slope with drainage.

- Provide appropriate single-phase power point with good lighting arrangement in Garbage Room.

- Provide outside the opening flush door to the garbage room.

- Chute duct slab to be closed in garbage roof after installation of the chute.

Garbage Room Sizes Required

| TYPE OF CHUTE | SIZE OF GARBAGE ROOM | ||

| – | L | W | H |

| STANDARD CHUTE | 1500mm | 1500mm | 2500mm |

| SEGREGATION CHUTE | 2100mm | 1500mm | 2500mm |

Segregation System

As per Municipal norms, segregation of “DRY”(Recycling)& “WET”(Biodegradable) garbage is required and shall be collected in separate collection Bins. We Provide to Segregate and collection of garbage by using one chute. It is fully automatic and one user at a time.

- Press any button “DRY” or “WET.”

- Busy Indicator and hoppers remain locked for all other floors.

- Chute Converts to respective mode “DRY” or “WET” by rotating the flap door in the garbage room.

- Operated hopper unlocked with an indication of selected garbage.

- Open hopper manually & Drop respective garbage bag. This bag goes to the appropriate trolley.

- Auto closing hopper resets the System for the next use. Total change over time of 10 seconds.