Smoke Chute System

When an emergency arises, such as an unexpected fire, the elevator is out of commission, or the stairs are filled with smoke, you are stranded. As buildings have grown larger and higher nowadays, emergency safety rescues have become more difficult and unreachable. Using a crowded stairway to escape a building is quite terrifying when there’s a fire. The superior choice is unquestionably a chute because it operates with little mechanical or electrical help. Serves as an escape route from a covert hideout during terrorist strikes or as a means of escape during disasters like fire or earthquakes.

The building members are proud of where they live and work. Therefore the last thing you would want is for them to suffer in a fire or other emergency because there aren’t enough exits, the stairs are blocked, or the lift is shut off.

In light of the preceding, Olive Enviro Industries would like to introduce the Smoke Escape Chutes technology. This would be a perfect solution in the event of a fire, where it effectively brings occupants safely to the ground within the first few minutes, assuring your people that they will have a means of escaping under these trying conditions.

Benefits of Smoke Chute

- Quick and secure evacuation

- Potential for more than 15 people to be evacuated every minute

- Equally appropriate for pregnant women, newborns, unconscious individuals, and persons with disabilities

- In a single chute, heights of 100 metres and higher are achievable

- Confirms a smooth, regulated, and controlled sliding movement

- Every escape chute longer than 15 metres has a ground anchor to withstand wind movement

Features of Smoke Chute

- The installation space needed is minimal

- It is enduring and little

- Possesses a smooth sliding

- Visual protection

- Guaranteed to support a heavy load

- Safely distributing the load

- The chute weighs roughly 1.4 kg per metre

- Its fabric is thick and sturdy

- It is strong in the face of the wind

Application of Smoke Chute

- Hospitals, schools, kindergartens, office towers, and public spaces

- Old historical structures and individual homes and properties

- Department stores and tower building

- Gas, nuclear power, the public sector, and oil rigs

Making of Smoke Chute

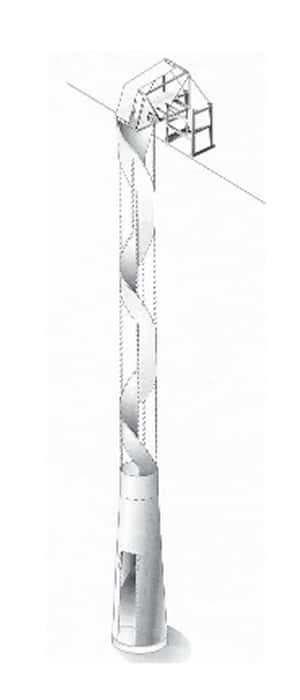

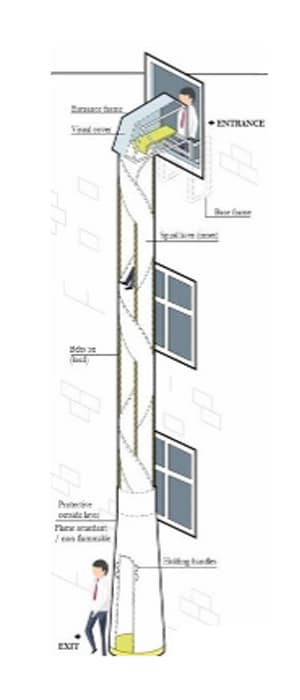

There are two or three tiers in the smoke chute

- The first layer controls speed decrease and is an internal spiral sliding layer. Its spiral shape allows for a controlled descent.

- The second layer is designed to support weight; five separate belts support the weight load. Each belt can carry a minimum of 2.900 kg (breaking load) and a maximum of 3.400 kg, for a total load capacity of 14 tonnes. Alternately, for economic reasons, it can be supported by one belt for very light and small descents.

- As an exterior protective layer is heat and flame resistant up to 800°C, the third layer is an outside layer created for the oil and gas sectors to manage the heat.

For maximum stability and longevity, both the inner and outer layers of our escape chute are made specifically for usage in Germany. In addition, the fabrics are certified water repellent, UV-resistant, and flame retardant by standards DIN 4102 (B1) and DIN 5510-2.

How Smoke Chute Works

- Emergency escape vertical chutes with an inbuilt spiral slide provide a safe descent, at a constant pace of 2 metres per second, without any injuries, and without the need for outside help.

- It requires no prior training to use and is a simple method. Before diving in, some people can have doubts, but once they do, they discover how simple it is.

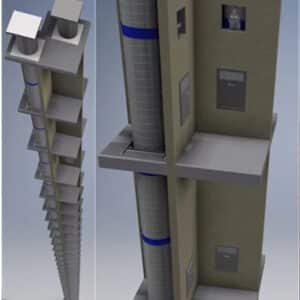

Single / Multi-Entry Chute System

- A chute with a single entry point enables emigrants to enter at one end and exit at the other.

- The multi-entry system has a single exit point and enables emigrants to enter the chute at various levels through multiple access points located throughout a structure.

Types of Smoke Chute System

Internal Smoke Chute System